LED technological advancement has eliminated all limitations from using traditional DIP screens with the invention of SMD and COB LED display screens. While there are many other variations in LED screens, the competition among SMD, DIP and COB is quite intense because all technologies offer incredible benefits with customer satisfaction and efficiency.

Factors to Consider for LED Screens

It’s not that easy to find an appropriate LED display supplier and led display, especially when the competition is too high and buyers have to go through a wide list of features, specifications and options to come up with an appropriate one. But, when it comes to getting a list of general factors to choose the right LED display screen, below is what experts used to mention:

Pixel pitch

Screen resolution

Screen Size

Brightness level

Display effects

Viewing experience

Smoothness and clarity

Power efficiency

Contrast level

Color uniformity

Below is a brief comparison of the three alternatives to help buyers decide which one to go for:

1. DIP (Dual Inline Package) LED Display Screen

DIP package is the abbreviation of dual inline-pin package, commonly known as plug-in lamp type, is the earliest used; led lamp (led display commonly used are F546 and F346) inserted into a special PCB board, after wave soldering to produce semi-outdoor module and outdoor waterproof module.

DIP display screens have been in existence since years now. Their strong and efficient technology has made them a preferable choice for marketing industries. DIP offers the same visual experience as SMD display. The thing that makes it different from SMD is separate LEDs present in the structure. It has blue, red and green LED dots as points on the screen that a human eye can easily see.

DIP is still the best choice for making outdoor LED screens, especially in the field of large screens, high brightness (>8000nits) screens, or some special applications.

2. SMD (Surface Mounted Device) LED Display Screen

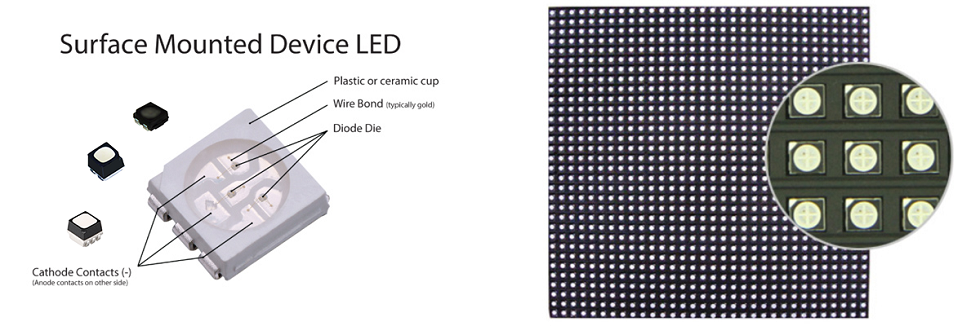

SMD technology is completely opposite of DIP technology. It doesn’t use three colors of LEDs (red, blue and green); rather, it makes a single point by grouping them. The resultant is either a dot or a square, where the dot has diameter of a few millimeters.

Unlike DIP screens, SMD LEDs are not visible separately and therefore, the gap between each pixel is almost unnoticeable. The best thing about SMD LED is that it has unmatched resolution, with a pixel pitch of 1.2 mm or more.

Another distinguishing factor of SMD LEDs is the number of diodes and contacts present in their structure. SMD LED chips usually have more than two contacts, which is significantly better and different than typical DIP LEDs). They can have maximum 3 diodes on one chip, where each diode will be having its own circuit. This circuit will have one anode and one cathode that will make 2, 4 or 6 contacts on an LED chip.

With this configuration, SMD chips show incredible versatility as there are blue, red and green diodes. With these colored diodes, any color can be created with significant output level adjustments. So, users are rest assured about getting clarity and smoothness in the images no matter what they are viewing and from where.

SMD display screens pride themselves for offering incredible color consistency with better picture quality and screen resolution. The screen is capable of maintaining good color mixture because it has grouped LEDs for seamless blending.

3. COB (Chip on Board) LED Display Screen

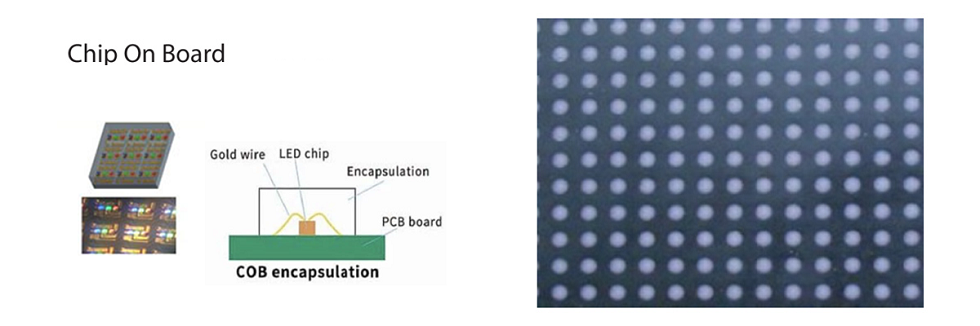

Chip on Board or COB is a kind of LED display that has an integrated circuit wiring bonded to a printed circuit board having LED lamps. These lamps are present in the front while ICs at the back that complete a COB LED module. When these modules are joined together, they create an LED display.

COB display encapsulates the LED chip technology, display technology and encapsulation technology. This enables COB LED screen to be widely used for a number of purposes.

COB LED display doesn’t have diameter per single LED due to its micro size. This makes production process easy with fewer expenses. COB display screens pride themselves for being thermal-resistant with high-density packaging.

Another important consideration is its anticorrosion, anti-static, waterproof, anti-oxidation; dustproof and damp proof capabilities that make this LED a significant purchase for a variety of purposes.

Which is better?

While each type of LED display screen holds an edge over the other, there is nothing like making claims about which one is better. The real fact is that whatever display screen meets the requirements, it is a good purchase. In other words, customers has to analyze their needs and evaluate these three SMD, DIP, COB LED display cost in order to figure out which one is capable to fulfill them.